Originally published in Fast Company

I spend my days talking to executives who believe their teams are performing near full capacity. They point to busy calendars, overflowing inboxes, and long hours as proof. But the data tells a different story—and it’s costing millions.

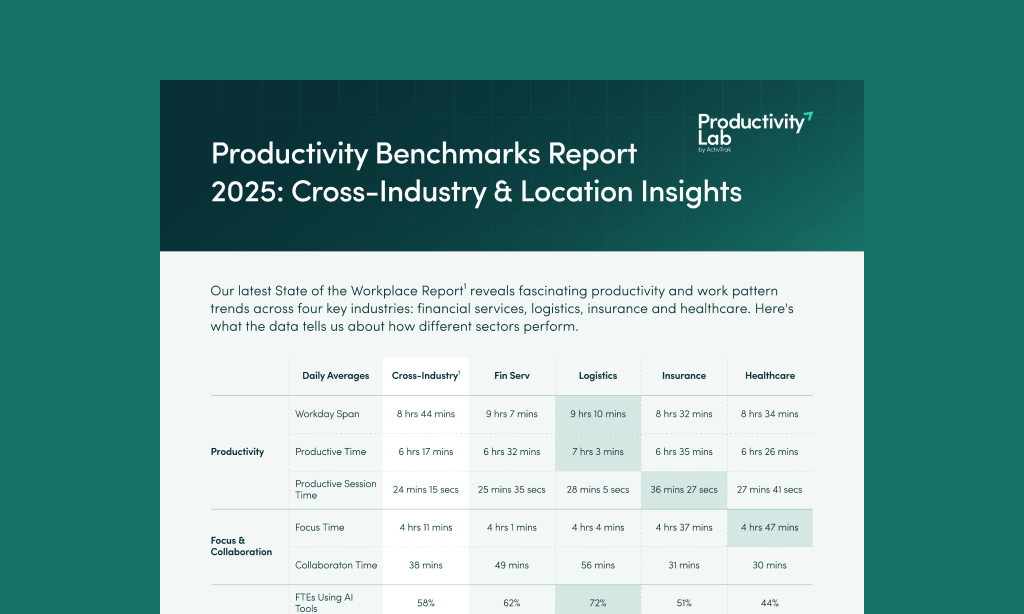

Our latest Productivity Lab analysis of more than 300,000 workers across 5,619 organizations reveals a costly reality: Companies lose $11.2 million in productivity per 1,000 employees every year. Utilization averages just 87% of capacity, while payroll costs continue at 100%—the equivalent of paying for 130 workers who aren’t contributing.

Most leaders don’t realize this is happening. Across all tracked organizations, that gap adds up to $2.86 billion in lost productivity each year, based on an average productivity goal of 6 hours and 50 minutes of productive work per day.

When ‘Busy’ Isn’t the Same as ‘Productive’

The data goes further, showing that 58% of staff failed to meet productivity goals set by their own organizations. By industry, the gap is significant: Computer hardware has the highest underutilization rate at 71%, while logistics is lowest at 41%.

One likely factor is the nature of the work and the corresponding work culture. Industries like logistics often operate with built-in accountability—billable hours, compliance requirements, and mission-critical timelines—that make performance visible and consequences immediate. These structures tend to surface productivity gaps faster than in roles where outputs aren’t directly tied to fixed deadlines or regulatory oversight.

The Leadership Assumption That Costs Millions

Our benchmark data shows small organizations lose $162,000 to $542,000 in untapped capacity annually, while large enterprises see losses of $3.7 million to $3.9 million. Even small inefficiencies multiply quickly and payroll costs are only one component of the story. Additional waste related to underutilization begins to creep in such as disengagement, quality issues, and collaboration shortcomings.

The issue isn’t laziness or poor motivation—it’s structural. Traditional management focuses on hours worked or activity levels, which overlooks the core question: Is the work creating measurable value? When activity isn’t aligned to outcomes, organizations dilute the impact of their teams’ efforts.

Turning Underutilization Into Growth

Addressing underutilization isn’t just about cutting waste—it unlocks capacity for work that drives growth.

I’ve seen companies change their trajectory by measuring actual output against capacity, then redesigning roles so people focus on what they do best: problem-solving, relationship building, and strategic thinking.

The most successful organizations share three traits:

- They measure productivity by activity AND outcomes—focusing on work volume alongside the value created.

- They build operational visibility instead of assuming performance—identifying bottlenecks and barriers before they impact results.

- They treat workforce optimization as a revenue growth strategy, not just cost control—using freed capacity to drive innovation and competitive advantage.

This is a solvable problem. It’s not about asking people to work harder—it’s about working smarter, with clarity on what work is happening. From there, it’s about acting on those insights to eliminate bottlenecks and channel capacity toward high-value work that is core to each role.

A Practical Playbook for Closing the Gap

The first step is to take stock of how productivity is measured today. Many organizations track time spent or activity levels without connecting them to real value creation. Incorporating outcome-based metrics—such as completed deliverables, customer impact, or revenue contribution—creates a much clearer picture of performance.

Next, examine where work slows down. This often means mapping processes end to end to identify bottlenecks, unnecessary steps, or recurring delays. In some cases, this exercise reveals quick wins—like automating routine tasks with AI—that free up hours without adding headcount.

Visibility is critical, but it must be purposeful. The goal isn’t to monitor for the sake of watching—it’s to uncover where good work gets stuck and why. This could involve implementing reporting tools that highlight delays or variances from plan so managers can intervene before deadlines are missed.

Finally, treat the capacity you recover as an investment, not just a savings. Redirect that time and talent toward strategic initiatives, innovation or customer-focused projects that move the business forward. Pair that with a regular cadence of process reviews to ensure inefficiencies don’t creep back in as teams and priorities evolve.

The opportunity to unlock capacity is hidden in plain sight—you just have to know where to look. Our benchmark analysis shows the data is already there for leaders who are ready to take advantage of it.